Hyshell 8509 is a P.F. novalac used in manufacturing resin coated sand (shell moulding resin) for the shell process (croning process). This resin is particularly suitable for warm coating process where it shows optimum strength and curing characteristics. It is available in both powder and liquid form.

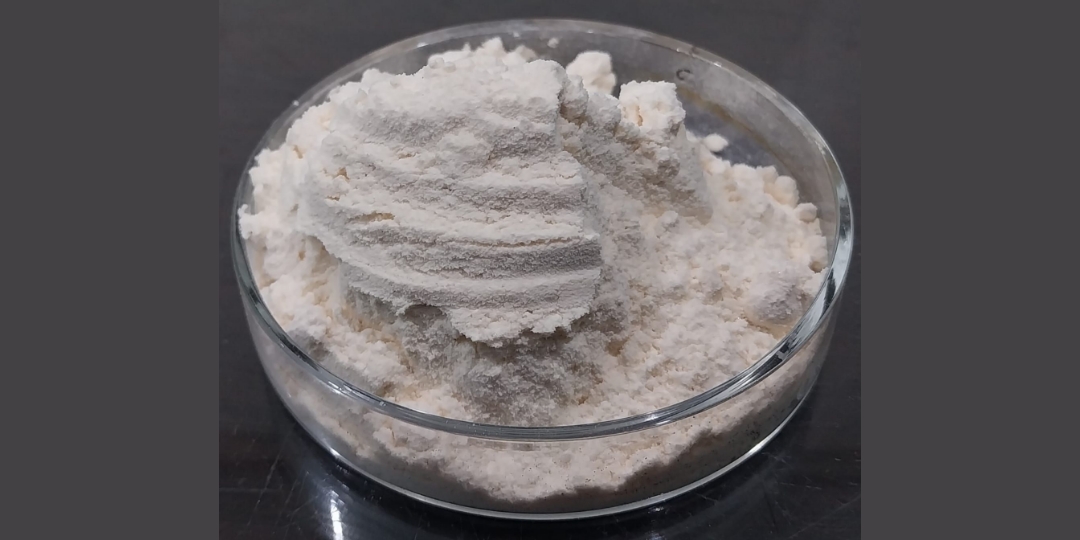

Description:

It is a free flowing transparent reddish brown solvent borne liquid resin having specific gravity 1.12 at 22ºc with solids around 70%. PH is adjustable within limits to suit various foundry applications.

Addition Rate:

Resin 2.5 to 5% by wt. of sand for cores & moulds. Catalyst 18% by wt. of Resin.

Mixing Procedure:

- Dry, cool and clay free sand is charged into the mixer along with powder Catalyst and mixed for 40 Secs.

- Liquid Resin is then added and wet mixing continued for 2-3 minutes.

- Hot air blow is then commenced and mixing continued until plastic bond is developed as indicated by near peak load of the motor and ammeter reading.

- This plastic bond then dries off and the mass breaks down to smaller lumps and then further to loose sand aggregate.

- It is then discharged through 1/16″ vibrating wise mesh and completely cooled before storage or use.

Standard Packing:

- Resin: 200 Kgs. in steel drums.

- Catalyst: 40 Kgs. in Polylined gunny bags.

Storage Life:

- Resin 6-12 months when stored in cool dry place in sealed containers.

- Catalyst infinite when stored in cool dry place in airtight packing.

Hyshell is recommended for its:

- Fast curing rate.

- Excellent strength.

- Easily controlled rate of investment.

- Resistance to hot deformation or distortion.

- No peel back characteristics under proper working conditions.